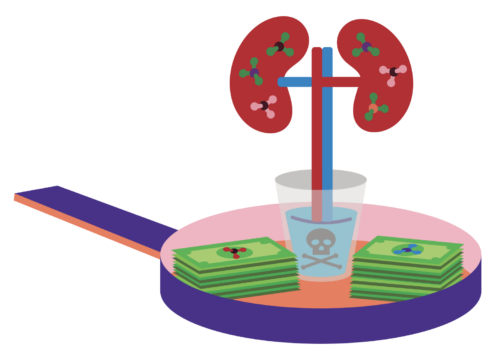

Art Courtesy of Luna Aguilar.

Life on Earth depends on interactions between carbon and hydrogen, as they come together to form bonds that serve as the backbone of many organic molecules. However, it is the element fluorine that forms the strongest single bond with carbon. Chemists tried to create these carbon-fluorine bonds in the late 1800s, and by the early 1930s, they succeeded by replacing hydrogen atoms with fluorine in organic molecules.

Their breakthrough led to the development of some of the most resilient compounds in organic chemistry today: per- and polyfluoralkyl substances, or PFAS, which all contain fluorine-carbon chains. This extensive family of synthetic compounds comprises thousands of chemicals known for their exceptional durability and resistance to degradation, earning them the fitting nickname “forever chemicals.”

Since their introduction into the market in the 1950s, PFAS have been incorporated into a wide range of products, from waterproof garments to non-stick pans to firefighting foam. However, mounting evidence indicates that these forever chemicals have infiltrated not only our consumer goods, but also our drinking water, our soil, and even our bodies.

“A Wonder of Modern Science”

The birth of PFAS can be traced to the so-called “Chemical Century,” which witnessed notable advancements in the field and the increasingly widespread use of synthetic chemicals across society. The chemical industry was deeply connected to military power and warfare during this period. For instance, DuPont’s Teflon (polytetrafluoroethylene)—one of the most notorious PFAS—was used during the Manhattan Project when creating warheads, liquid-fuel tanks, and even the atomic bomb dropped on Nagasaki in 1945.

Several of the researchers involved in the Manhattan Project would go on to join the multinational company 3M to further develop PFAS. By 1951, the company began producing perfluorooctanoic acid (PFOA), a PFAS. PFOA was sent to a DuPont plant in Parkersburg, West Virginia, where commercial Teflon products would be manufactured. Around the same time, 3M also began producing Scotchgard, a brand of fabric stain and water-repellant sprays, using another PFAS called perfluorooctane sulfonic acid (PFOS).

PFAS were also used in Apollo space missions and emerging medical technologies, as seals on ventilators and as a coating for medical catheters. It seemed PFAS could be used in everything, everywhere, and was heralded as a “wonder of modern science.” The optimism of the era is reflected in the pages of the May 1956 issue of the Yale Scientific Magazine (Vol. 30 No. 8), which proclaimed that “from [Teflon’s] unique characteristics a brilliant future can be inferred.”

Unique Chemical Characteristics

As past YSM writer Robert J. Lontz laid out in that article, PFAS owed its industrial desirability to a unique combination of properties that made it well-suited for a wide range of applications.

Lontz first pointed out that the strong dielectric properties of PFAS make it an excellent electrical insulator, capable of preventing the flow of electric current through the material. Due to the strength of its carbon-fluorine bonds, PFAS are also chemically inert, meaning they remain stable and unreactive when subjected to various other chemicals or environmental conditions.

Teflon also offers, as Lontz wrote, a “waxy, slippery surface.” PFAS are well-known for their non-stick and low-friction properties, and have thus been used to create surfaces that do not adhere to other materials, making them easy to clean. Finally, PFAS are inherently water-repellent. They form a protective barrier on surfaces, making them ideal for applications such as water-resistant clothing or any materials that need to repel moisture.

A Double-Edged Sword

Nearly seventy years after Lontz’s article was published, it has become clear that the same unique characteristics that led to PFAS being dubbed “forever chemicals” are closely intertwined with their potential health and environmental risks. “Certain members of the PFAS family have come to light as biologically and environmentally persistent compounds with bioaccumulation potential in the last few decades,” said Gary Ginsberg, the director of the Center for Environmental Health for the New York State Department of Health, a former member of the EPA’s Science Advisory Board, and a clinical professor at the Yale School of Public Health.

In contrast to other persistent organic compounds, which primarily accumulate in fats, PFAS behave differently. Being water-soluble, they can follow natural solubility pathways by dissolving in water and infiltrating groundwater. This dispersal can lead to additional ecological impacts, including uptake into fish and drinking water supplies.

In 1998, Wilbur Earl Tennant, a farmer from Parkersburg, West Virginia, noticed his cows were dying from a mysterious illness. He approached lawyer Robert Bilott who would go on to investigate the DuPont company, whose chemical plant was located in the town. By 1999, Bilott filed a federal lawsuit against DuPont for dumping PFOA waste into local water supplies. In April 2003, the Environmental Protection Agency (EPA) initiated a comprehensive review of the synthetic chemical, raising concerns about its prevalence.

Of particular concern to the EPA was the early evidence suggesting that traces of PFOA could already be detected in the blood of nearly all U.S. citizens. According to a study based on 2011-2012 data from the National Health and Nutrition Examination Survey (NHANES), PFAS was detected in the blood of ninety-seven percent of Americans tested.

This statistic becomes all the more alarming when considering the well-established health hazards associated with PFAS exposure, which include cancer, thyroid disorders, developmental issues, and disruptions to the immune system. “One of the main drivers for the dose-response [of PFAS] seems to be their unusual propensity to have long human half-lives on the order of three to six years,” Ginsberg said.

Scares & Successes

Both PFOA and PFOS were phased out of production and use in the U.S. in the mid-2000s through industry agreements with the EPA. Data from the NHANES, which has done bio-monitoring work since the late 1990s, has shown that levels of PFOA and PFOS levels in the U.S. population have been declining. Notably, blood PFOS levels declined by more than eighty-five percent from 1999 to 2018, and blood PFOA levels declined by more than seventy percent.

Many state policymakers have been increasingly focusing on the issue of PFAS, particularly over the past five years. Notable actions were taken by Vermont, which established maximum contaminant levels for PFAS in water, and Minnesota, which prohibited specific flame-retardant chemicals in furniture and children’s products. In 2020 and 2021, states continued to address concerns about PFAS with numerous bills, targeting regulation in firefighting foam, consumer products, and drinking water.

According to Ginsberg, current concerns include occupational exposures and the toxicology of newer generations of PFAS. Krystal Pollitt, an associate professor of epidemiology at the Yale School of Public Health, shared a similar view. “One of the challenges with measuring these chemicals is that there are over ten thousand PFAS and current EPA methods only cover about twenty of them,” she said.

Given the known health risks associated with PFAS, it is perplexing that it took until March 2023 for the EPA to propose the National Primary Drinking Water Regulation (NPDWR). If enacted, the NPDWR would represent the first national drinking water standard for PFAS, imposing enforceable limits on levels of six common PFAS chemicals—including PFOS and PFOA—in drinking water. Unfortunately, this much-needed measure arrives far too late for many who have already endured the adverse effects of PFAS exposure in the seven decades since its introduction into commercial use. Why did it take so long to take federal action against PFAS?

The Precautionary Principle’s Call

The heart of the issue lies within our regulatory systems. “The challenge lies not only in regulating PFAS but in regulating any chemical or substance,” Ginsberg said. He explained that it has been decades since the EPA last determined the need for a new maximum contaminant level or implemented additional regulations for any substance. This is due in part to the challenges surrounding implementing new regulations and navigating through multiple levels of governmental policy review.

The story of PFAS and the NPDWR underscores a disconcerting reality that, for decades, there has been a failure within regulatory and legislative frameworks to proactively address emerging environmental and health threats. While the EPA is working to be more predictive of such threats by employing advanced Toxcast testing methods and their Unregulated Contaminant Monitoring Rule testing program to detect emerging contaminants in drinking water, it has become evident that creating meaningful change within this system is a process that takes time.

“The optimal way forward would be to regulate PFAS as a class,” Pollitt said. As of now, researchers including Pollitt are still working to understand the health impacts of PFAS. They employ various methods, such as measuring PFAS levels in biological samples and collaborating with numerous epidemiologists to develop scalable solutions for assessing exposure. Had the precautionary principle, which advocates that a substance be proven safe before being released into the market, been integrated into our regulatory framework, this could have been a different story. We would not only foster a culture of prevention rather than reaction, but also show that public health and environmental safety take precedence over economic interests.

The story of PFAS serves as an urgent call for change and as a stark reminder of what can happen when scientific innovation goes unchecked. And this story is not unique. “Look at pesticides and DDT; it was only after decades of broad use without appropriate safety testing and risk assessment when they were then phased out,” Ginsberg said. “PFAS is just one example of us not doing our homework before releasing chemicals to the market.”