Bioprinting 3-D organs with soft, tissue-like materials

Cars, toys, knick-knacks and prototypes—the array of objects that can be brought to life with a 3D printer is vast and growing. 3D printers are getting more impressive, capable of making anything from usable engine parts to full-scale houses. Now, an even greater goal is within reach: printing the brain.

3D printing technology has recently made significant breakthroughs in diverse fields, including medicine, engineering, and design. We live in a world where a technician can print a prototype of an invention in just a few hours. The ability to create a 3-D object, one that models the intricacies of a physical system that was once only imaginable on a computer screen, has opened the doors to hundreds of applications, particularly in the field of biomedical engineering. These ambitions are coming to fruition thanks to the work done by researchers at Imperial College London, whose novel 3D printing process creates material that can closely model the human brain.

Models of the human body made by 3D printing have been around for the past 20 years. For example, Yale researchers at the Center for Engineering Innovation and Design successfully printed a large-scale model of a neuron in 2015. Academically, this provides a new “dimension” to the way students and neuroscientists can observe and study the human neural system. Bioprinting takes this technology one step further. 3D bioprinting uses the same techniques as a standard printer, which ejects material to construct precisely mapped layers, but uses a combination of cells and hydrogels as its material instead.

Bioprinting technology has already made waves in drug testing, regenerative medicine, and even surgical tissue transplants. The challenge of using these printers with real people, however, is that whatever is produced often cannot accurately represent an actual human organ; the product might be too stiff or too dense, or it might misbehave when placed in the same conditions as the organ it is modeled after.

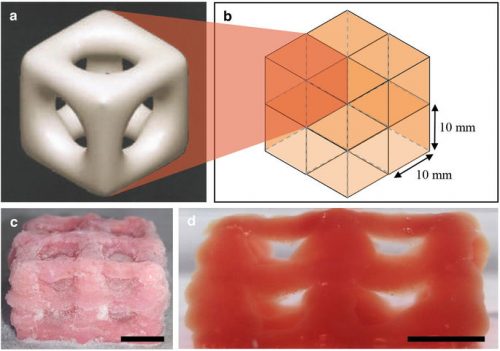

Fortunately, cryogenic freezing is a promising solution: a team of researchers at Imperial College London has developed an innovative modification to standard bioprinting in which a solution of a composite hydrogel (CH) is frozen rapidly to produce material that is as soft as the tissue in the brain or lung. The procedure uses precision technology to accomplish a process known as rapid cooling. When a liquid material is cooled below its freezing point, its transitions into a solid. The final product is much harder than the liquid, in the way water is much “softer” than ice. Controlled cooling slows down the moving molecules of a liquid until they can’t move around. These molecules try to arrange themselves in the most tightly packed way possible so that when the material freezes, it is stiff. This rearrangement of molecules takes some time, so if one can rapidly freeze a material, the final product will be a much softer, more flexible solid because the molecules didn’t have time to pack optimally.

Using this principle, the new cryogenic bioprinting procedure uses dry ice to rapidly freeze the CH ink solution as it extrudes layer by layer. The result, according to Zhengchu Tan, the postgraduate researcher spearheading the procedure, is something that now enables the creation of arrangements that match complicated biological structures, such as the tissue in the brain. The innovative procedure provides an alternative to cast molding organ replicas, where the hydrogel is poured into a mold. “That’s how they’re normally made, but you can’t get complex geometries like that—hollow geometries,” Tan said. By using a 3D printer, one can now create the complex interiors of distinct shapes and textures, not just the exteriors.

Another significant consequence of the cryogenic freezing method is that the printed tissue behaves similarly to the brain in the appropriate environment. “The resulting material structure is as soft as the brain, so while it does hold its shape, the brain is also deformed under gravity, and that’s a massive issue during neurosurgeries,” Tan said. Their bioprinted tissue successfully models this behavior. When hydrated and kept in the same conditions as the brain, the material is also able to keep its shape or deform as necessary.

Tan’s research paves the way for enormous opportunities in medical research. It may soon be possible that 3D printed organs can replace live subjects for drug testing or risky surgical practices. Day by day, layer by layer, bioprinting technology overcomes challenges in innovative ways. With each advancement, more medical dreams become a reality as we print our way to a better future.

Sources

[1] Interview with Zhengchu Tan, Imperial College London, 2/01/2019