Every second, metals that form the components of our day-to-day electronics are thrown out. There are currently no efficient methods for recycling them, yet our need for these metals remains strong. Yale researchers have developed a solution that salvages metals at their “end-of-life” stage and allows them to be used once again.

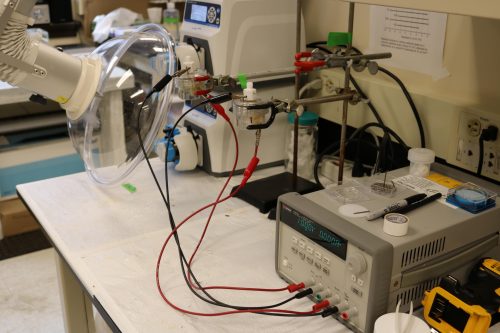

Megan O’Connor, a research scientist who works with Desirée Plata, a professor of Chemical and Environmental Engineering at Yale, has developed an electrochemical filter that selectively removes metals using an applied electric potential. These filters are small containers able to attract unique elements from a “waste stream” of dissolved metals based on the potentials they apply. Some metals recovered in this research include common “bulk” metals like copper (Cu), while others are rare earth and specialty elements (RESE) like europium (Eu).

The device functions by using an electric potential. Electric potential describes the willingness of electrons to move from one point in space to another, and is used in this device to return metals in a solution back to their solid form. Dissolved copper, for example, needs about two volts of potential to maximize recovery. O’Connor discovered that although two volts works well for copper, different voltages work well for other metals. This finding means metals can be individually retrieved from waste streams according to the type of voltage applied. Other factors such as pH and flow speed of the waste stream can also affect the amount of metal recovered.

Though all metals should be recycled, RESE metals are more concerning in electronic waste (e-waste) because they are difficult to mine. The U.S. Department of Energy published a “criticality” matrix in 2011 to determine the importance of certain earth metals based on political, social, and regulatory factors. RESE metals are included for their potential supply-demand imbalances and for their inclusion in important technologies. Some of these metals are even used for developing cleaner energy technologies. All metals, however, have the potential to run out if not properly recycled.

“If we keep using the amount of earth metals the way we have, we will run out,” O’Connor said.

This invention would efficiently recycle metals thrown into the stream of e-waste, such as neodymium and dysprosium, which are used as magnets in certain vehicles and in wind turbines. This new technology could also return metals back to manufacturers, increasing their supply and lowering prices of many electronic goods for consumers.

“O’Connor’s method for reclaiming metals and returning them to manufacturers seems to be a better alternative to other recycling approaches,” Plata said. O’Connor’s company, Nth Cycle, plans to scale up the device. Her company’s funding proposal is one of nine currently under review in the Oak Ridge National Laboratory Innovation Crossroads Competition, which is sponsored by the U.S Department of Energy.

References

[1] Interview with Megan O’Connor (inventor), CEO of Nth Cycle, LLC, interview on 01/30/2018

[2] Interview with Professor Desiree Plata (research advisor), Plata Lab, Yale Department of Chemical and Environmental Engineering, interview on 01/30/2018

[3] O’Connor, Megan P., et al. “Electrochemical deposition for the separation and recovery of metals using carbon nanotube-Enabled filters.” Environmental Science: Water Research & Technology, vol. 4, no. 1, 2018, pp. 58–66., doi:10.1039/c7ew00187h.

[4] https://seas.yale.edu/news-events/news/recycling-rare-earth-metals-e-waste?destination=node/2896 – used webpage for general information on the research development

[5] U.S. Department of Energy, Critical Materials and Strategy, December 2011, “Chapter 4: Supply and Demand Projections”