Image courtesy of Frank Shi.

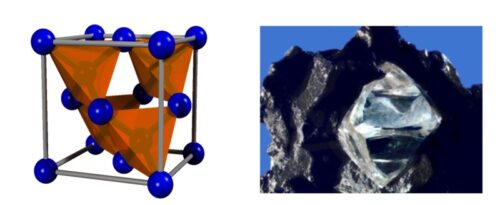

For centuries, alchemists have been seeking ways to convert substances into one another. While water to wine or metal to gold may not be possible yet, a research team has identified a method of converting diamond to metal solely through mechanical strain. The team, led by Suba Suresh, Ju Li, and Ming Dao, used quantum mechanical and machine learning simulations to identify a method of reversible metallization in diamond nanoneedles. Under enough mechanical strain, diamond nanoneedles were converted to metal without undergoing a phase transition, and without causing structural irregularities in the material.

The team was interested in studying diamond due to its properties as a semiconductor. “Diamond has a very high degree of hardness and stiffness, which makes it ideal for a variety of applications,” Li said. The extreme physical properties and biocompatibility make diamond applicable to mechanical, electronic, biomedical, and energy fields.

Previous research on nanoscale diamonds undergoing mechanical strain demonstrated that diamond nanoneedles of different geometries (monocrystalline and polycrystalline) and diameter around three hundred nanometers can be reversibly deformed under certain conditions, and this study sought to find out how much metallization could be safely achieved under those conditions. “Past research on nanoscale diamond and advancements in machine learning of the electronic and phonon structures of diamond has created new opportunities to address new scientific questions,” Li said.

In particular, the team sought to demonstrate whether diamond could be completely metallized under mechanical strain. They also wanted to identify the lowest strain energy required to achieve “safe” metallization—metallization that would not cause “phonon instability”. A phonon is the uniform vibrational motion of atoms at a single frequency in a material with a lattice structure, such as diamond, so phonon instability could cause irregularities in the properties of diamond. In addition, the team studied diamond nanoneedles of various geometric structures, to identify how different crystallographic and geometric variables would influence the metallization process.

Frank Shi, a graduate student working on this research project, developed a machine learning algorithm to model pathways to metallization for different geometries of diamond nanoneedles. “For this project, we used an algorithm based on an artificial neural network approach,” Shi said. The team developed calculations and simulations for the elastic straining of diamond, the results of which were used to determine the optimal properties for metallization of diamond, demonstrating that “safe” reversible metallization could be achieved under a certain degree of elastic strain. Further strain, however, would cause phonon instability in the diamond, which could trigger a phase change from diamond into graphite, another form of carbon.

Using experimentally-validated simulations, the team found that the optimal conditions for the metallization of diamond nanoneedles depend on the geometry of the diamond and the nanoneedle orientation. In this research, three different nanoneedle orientations were studied, and each was found to have different strain possibilities. Beyond the three configurations studied here, nanoneedles with more complex geometric features can be designed, simulated, and studied with machine learning, which would further improve the possibilities of diamond metallization. “There is a lot of possibility for future research in this field because more complex needle geometries can be designed,” Li said.

The results of this study offer new possibilities for deliberate and extreme alteration of the functional properties of diamond using strain engineering, which could have applications in many different fields of science, technology, and engineering. “Photons and excitons are the main tools used for quantum information processing,” Li said. This means that the results of this research carry implications for other fields including quantum sensing and quantum computing. In addition, according to Li, the demonstration of complete metallization of diamond without phonon instability is a groundbreaking development for power electronics, a field in which diamond is widely used due to its properties as a semiconductor, a material with less conductivity that a conductor (such as copper), but more than an insulator (such as glass). When strained, diamond is transformed into a direct bandgap semiconductor, which means that electrons have the same momentum in both the valence band (the highest energy range where electrons are present) and the conduction band (where electrons “jump” to when excited, allowing conductivity to occur). Because absorbance increases with the thickness of a material, a device that converts light energy based on a direct bandgap semiconductor such as diamond would be able to absorb visible and infrared light with much less thickness than other materials, which could improve the design of devices such as high-efficiency photodetectors.

Citations:

Li, J., & Shi, F. (2020, October 26). [Online interview].Shi, Z., Dao, M., Tsymbalov, E., Shapeev, A., Li, J., & Suresh, S. (2020). Metallization of diamond. Proceedings of the National Academy of Sciences,117(40), 24634-24639. doi:10.1073/pnas.2013565117